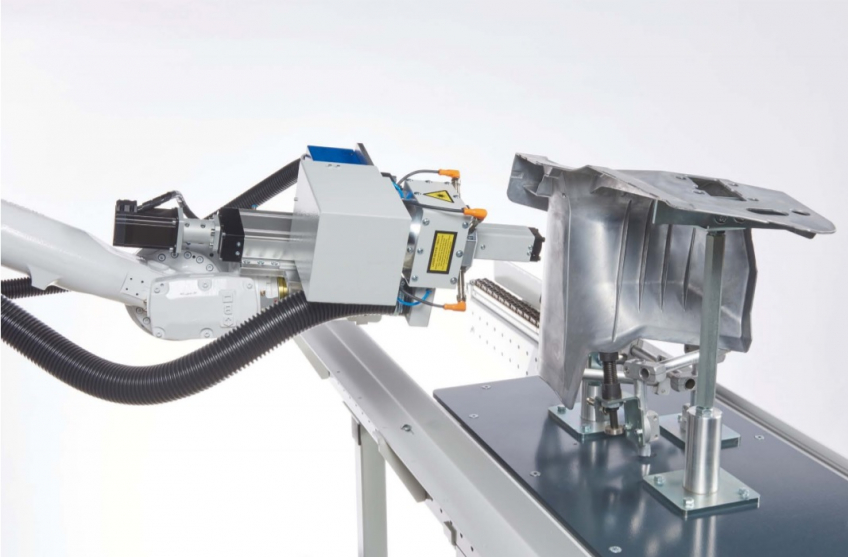

Laser engraving with our unique laser safety head

The term laser engraving is widely known and interested people know what to imagine under this term. What is the difference between laser engraving and marking, or laser description, we explained in the previous article entitled: Difference between laser marking and laser engraving. Now let's take a closer look at laser engraving, specifically the engraving of datamatrix codes.

Why are datamatrix codes engraved on products?

Engraved damatrix codes carry manufacturing information and have enormous durability, which is very important from the point of view of traceability. They are visible even with greater abrasion, even after surface treatments such as sandblasting or painting, which is their great advantage.

Specializing in laser technology, LINTECH has developed and engineered a special laser safety head for DMC laser engraving. This unique device engraves the datamatrix code into the aluminum casting at the very beginning of the production process.

Why is this solution unique? Especially because:

DMC can be engraved on the casting with a laser head immediately after it is cast (the temperature of the part exceeds even 200 °C).

The safety of the laser head complies with laser safety class. 1, thanks to its unique construction.

Laser engraving using a laser safety head is very precise and has high repeatability.

The laser safety head reaches a depth of up to 0.3 mm in a relatively short time with laser engraving.

Why use a laser safety head instead of a microdot for DMC engraving?

The quality of datamatrix codes created using laser engraving is higher than codes created by microdot or other conventional technology. This is especially evident when verifying these codes after subsequent surface treatments.

When creating DMC codes, it is important to achieve sufficient verticality of the walls of the modules so that a shadow is better formed in them and thus the code is easier to read. Which can be achieved better with a laser safety head than with a micropoint.

Unlike a micropoint tip, which can degrade due to material fatigue, the laser beam is stable, enabling high repeatability of the process. For these reasons, laser engraving is the best solution in most cases.

Watch the video - laser safety head in production: