How we extended the life of a stamps by 15 times without changing the stamping technology

One of our customers, company Dayton Progress s.r.o., contacted us with the problem of frequent complaints about marking of parts after surface treatment. Standard stamps supplied by another supplier had a short life span - after marking about 50,000 pieces, the numbers and logos were falling apart. The part was made of S420MC material and the marking should have been legible even after KTL treatment.

Customer requirements:

- increase the lifetime of the marking without loss of legibility,

- eliminate complaints related to visibility of the marking after painting,

- maintain the existing press parameters (cannot change the manufacturing process).

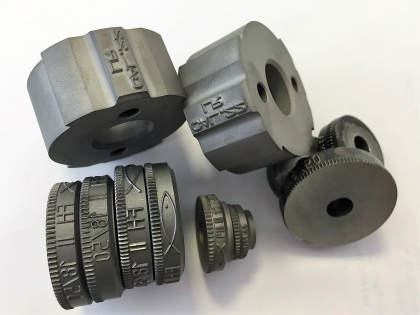

The customer provided us with several stampings from different periods. We performed a damage analysis in our laboratory.

Problems found:

- the stamps were scored, not milled.

- the geometry of the stamps was inappropriate - sharp transitions and insufficient angles.

- insufficient depth and improper profile caused the blades to break off quickly.

Our solution:

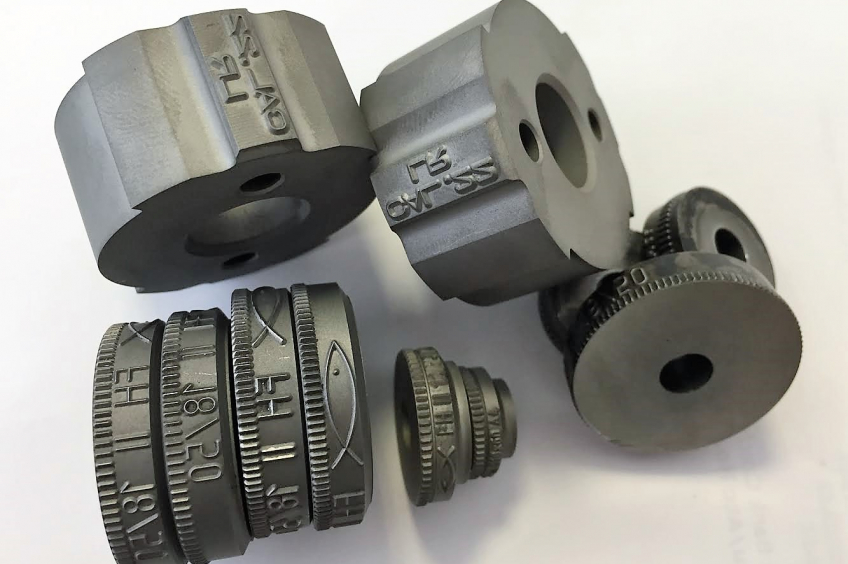

- production of new stamps by milling technology with optimized character profiles,

- using quality tool material according to our internal standards,

- test series of 2+2 pieces for direct comparison in production.

Result:

- our punches have reached a lifetime of 750,000 pieces - 15 times more than the original solution,

- the marking remains legible even after KTL surface treatment.

- complaints about the punches have been completely eliminated.

The customer states:

"We have been cooperating with LINTECH, spol. s r.o. since 2014, and since then they have proven to be a reliable partner countless times. We appreciate this cooperation and value their professional approach, fast communication and quality of work."

The right production technology can significantly extend the life of the tools, reduce tool replacement costs and at the same time increase the quality of the final product. Even small details such as font profile and engraving depth play a crucial role.

Do you have a similar problem? We would be happy to perform an analysis for you.