INTERESTING VIDEOS FROM CUSTOM PRODUCTION

You have the opportunity to look behind the scenes of the LINTECH custom production center, specifically on laser welding / surfacing and laser marking (re-marking) of datamatrix codes, which are originally marked with a micro-impact device.

Watch interesting videos on our YouTube channel.

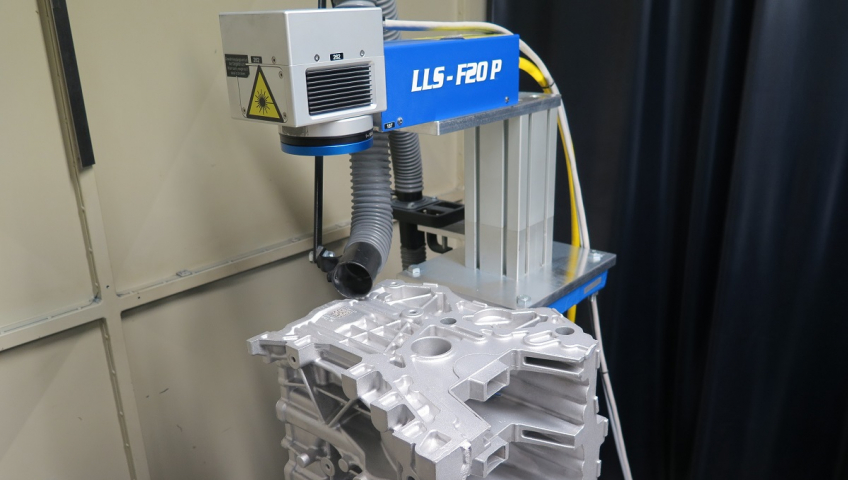

Relabeling of 2D codes using a laser beam

The original codes, which are marked with a micro-impact device, are illegible, so there is a need to correct them. The most convenient way to correct the original codes is with a laser beam, which "erases" the original 2D code and then creates a new 2D code that has 100% readability.

According to the customer's request, we will mark arbitrarily large series of products and parts. Whether laser engraving or laser marking.

Laser surfacing and welding

Custom surfacing and welding is an interesting laser application. Laser welding and surfacing can be used to repair tools, reducing the cost of purchasing a new tool.

Highly concentrated thin laser beam, delivers the required energy without lateral radiation exactly to the given repaired point. Therefore, very fine details, edges and shapes that cannot be repaired by other technologies can be welded on.

The video shows the precise laser welding of titanium.